Fall Protection Systems

The importance of fastening

All elements of fall protection systems, from anchor systems to harnesses, must meet the high standards of strength and resistance required under the relevant legislation to effectively protect workers from the hazards associated with working at height. Their effectiveness depends on each of the components, starting with the fastener. The fastener should be tested and certified together with all other system components, whereas it is often supplied separately and is rarely tested together with the other components. The advantage of having a single supplier for both elements (fall protection and fastening) is not only greater convenience, but also offers the security of having products that have been tested and certified together on different types of substructure.

Rothoblaas provides not only all the materials, but also all the necessary information for the correct design and installation of the system, from fastening on timber, concrete, steel and sheet metal to PPE, making even design calculations for installation purposes quick and easy.

The choice of fastener: a complex process

Each working environment presents unique challenges for the installation of fall protection systems, influenced by the nature of the substructure, construction material and environmental conditions. The selection of fasteners, therefore, cannot be separated from a thorough analysis of these factors:

Roofs and roofing: various types of roofing require specific solutions. For example, the fastener on a tiled roof may differ significantly from a fastener required for a metal or bitumen roof.

Walls and vertical structures: fastening to walls, whether of concrete or other materials, requires anchors that are not only solid but also compatible with the base material in order to ensure resistance to transmitted loads.

Special environments: in locations exposed to corrosive agents or extreme temperature variations, fasteners must offer additional corrosion resistance to maintain their mechanical properties over time.

In many cases, the anchoring systems for Rothoblaas fall protection systems already include the fastening rivets (we always supply an extra one for safety), which are ETA-certified and sealed with an EPDM washer. In other cases, where the fastening variables are many, such as for the installation of LOOP, Rothoblaas provides all the information on the types and minimum sizes of substructures and their fastening parameters, in order to be able to choose the most suitable one, making the structural calculation simple and straightforward.

In order to facilitate the choice of the fastening system according to actual installation conditions, Rothoblaas also provides its own calculation software, MyProjectwhich requires only entering the installation data.

Chemical anchors

Alongside mechanical anchors, then, there is the whole world of chemical anchors, which can be chosen for different reasons:

In cases where the base material is too fragile to withstand the stress generated by the installation of mechanical anchors, such as in the case of low-quality concrete, where a mechanical anchor could cause cracks or damage.

Where it is necessary to distribute the stress evenly over the base material, reducing the risk of cracking. This is especially important in critical applications such as fall protection systems, where safety is the priority.

In tight spaces or corners, chemical anchors can provide a safer and more reliable solution, as mechanical anchors may not expand properly or cause cracks in the material due to the pressure exerted during installation.

In situations where high load-bearing capacity is required, chemical anchors can offer superior performance compared to mechanical anchors because they allow for more efficient load distribution through the base material.

Under adverse environmental conditions, with exposure to chemicals, changes in temperature or moisture.

When choosing between one type of fastener and another, however, installation time must also be considered. The installation of a mechanical anchor is in fact much faster than any chemical anchor, because it does not require a waiting time before the load is applied.

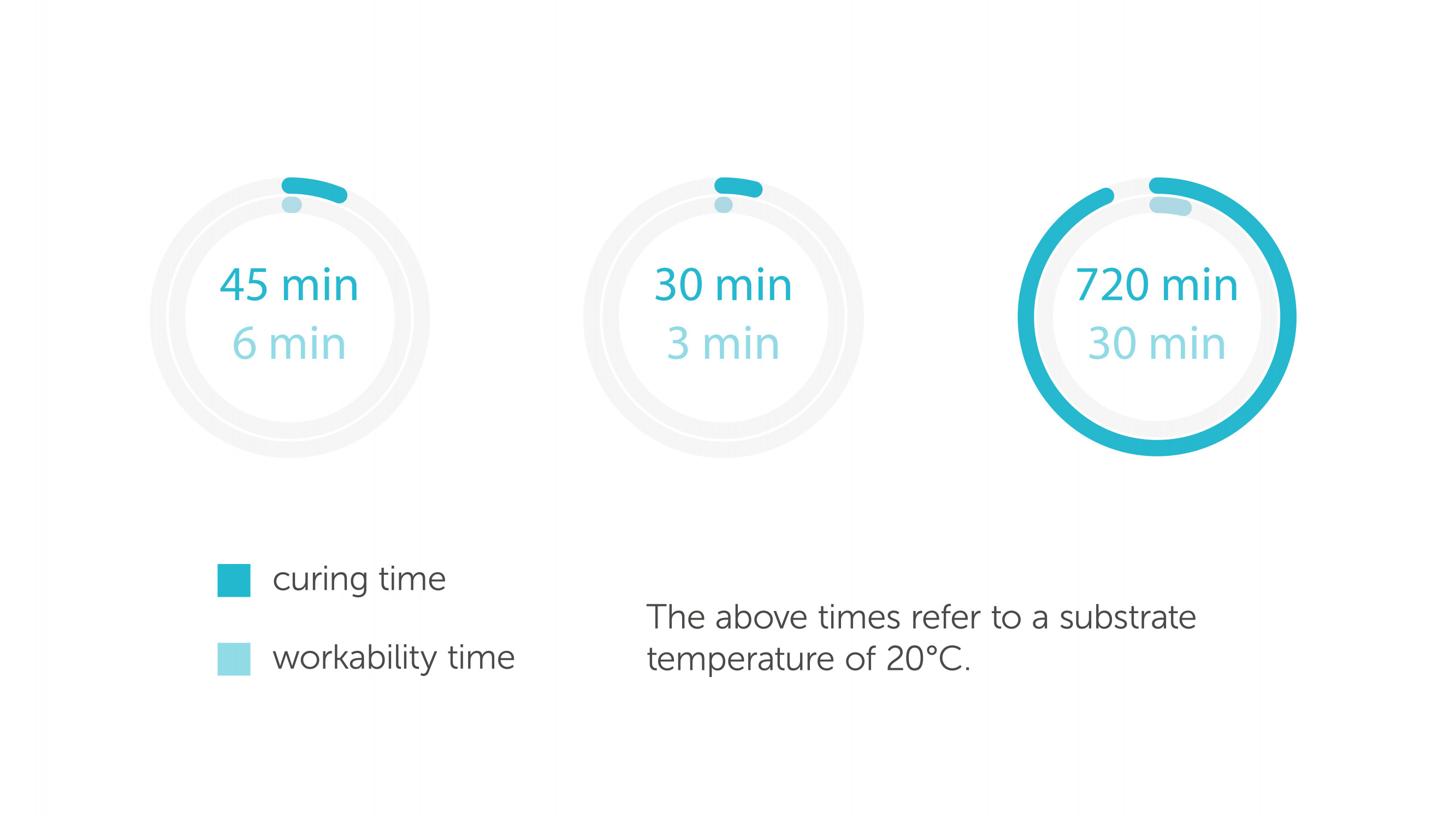

The timing of Rothoblaas chemical anchors varies depending on the nature of the product. The HYB-FIX hybrid anchor is the fastest, then we find theVIN-FIX vinylester anchor and then, the slowest, the EPO-FIX anchor.

While in terms of hardening time a vinylester anchor is much better than an epoxy, in terms of strength it is exactly the opposite. The hybrid anchor is a good compromise between the two criteria, because it has shorter installation times than vinylester and strength performance approaching that of epoxy.

There is therefore no absolute best anchor, only the one best suited to the specific conditions of use.

Rothoblaas "Gravity Lab" for testing and certification of fall protection systems

Integrated testing of fall protection systems, including fasteners, is crucial to ensure maximum safety and compliance with the technical standards required by the reference markets. Rothoblaas, with its advanced "Gravity Laboratory", perfectly embodies this philosophy, leading the way in the testing and certification of safety systems. Equipped with a 7.5 metre high drop tower, mobile platforms that facilitate assembly operations, and significant automation of operating processes, the Gravity Laboratory allows for the testing of both vertical and horizontal systems. CE-certified, not only speeds up product development time, but also provides the research and development team with an efficient, state-of-the-art testing environment, ensuring that each fall protection system undergoes rigorous testing before being introduced to the market. Thanks to these features, Rothoblaas guarantees its customers high quality products designed to offer the highest possible protection to workers.

Get in touch with us so we can work together right away to find the best solution for your needs.

All rights reserved

Technical Details

- 国家:

- Any

- 产品:

- LOOP HYB-FIX VIN-FIX EPO-FIX PLUS