Hybrid buildings: what they are and why they’re gaining ground in the construction industry

Hybrid structures, which combine different materials, are becoming increasingly prevalent in urban areas, driven by the growing demand for multi-storey buildings.

Engineers and architects focused on optimising construction processes and sustainability have identified hybrid construction as the ideal solution to meet market demands.

Hybrid buildings, such as timber skyscrapers with a concrete podium and core, are the product of a construction approach geared towards the development of multi-storey buildings and high-performance structures.

The principle behind hybrid construction is simple: combining materials to make the most of their individual strengths. Concrete is valued for its availability and stiffness, timber for its sustainability and lightness, and steel for its strength. The combined use of multiple materials addresses the needs of contemporary structural engineering, balancing building functionality with regulatory performance standards – such as resistance to fire – while also aiming to reduce environmental impact by limiting carbon emissions.

Timber-concrete composite structures: the most widespread

Timber-to-concrete combinations are among the most widely used hybrid systems in Europe and across the world. Although timber buildings always involve a combination of two materials – since the foundations are made of concrete – the term “hybrid building” is generally used to refer to timber skyscrapers, now increasingly commissioned by general contractors and public authorities alike.

Although buildings can be made primarily from timber, combining the latter with concrete offers significant benefits in terms of safety, durability and the feasibility of multi-storey construction. A key feature of timber-to-concrete technology is the use of reinforced floor slabs. In this system, the two materials work together to optimise structural performance: concrete provides compressive strength and increases load-bearing capacity, while timber contributes tensile strength thanks to its natural flexibility.

Ascent MKE, the tallest timber building in the world, is a hybrid structure

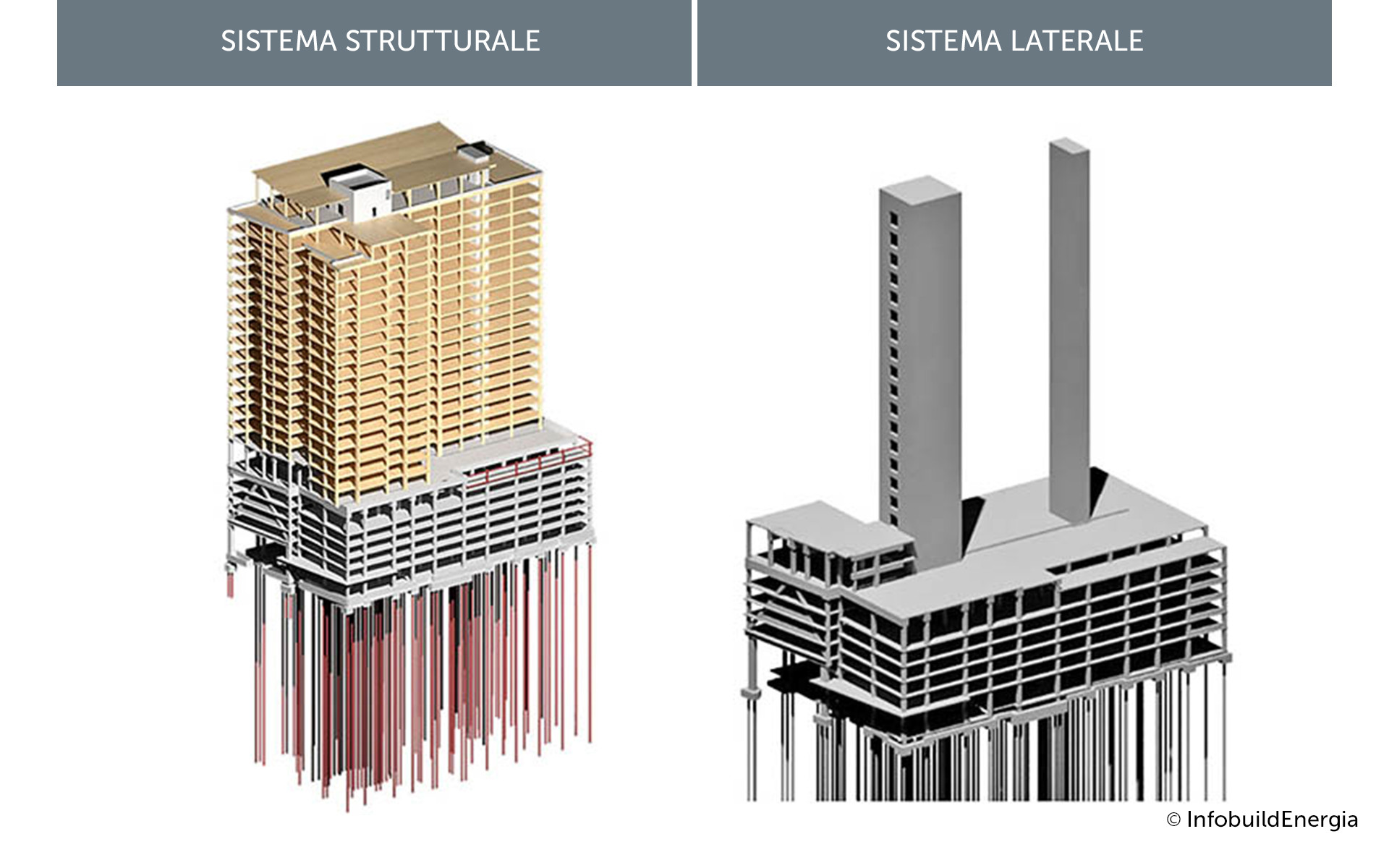

The Milwaukee tower, recognised as the tallest timber building in the world, stands out for its hybrid design. Rising to 86.5 metres, the structure is built on a seven-storey reinforced concrete podium, designed for commercial use, topped by 18 storeys in solid timber for residential use, which sit directly on the reinforced concrete.

The lateral structural system also features two concrete cores that serve both structural and functional purposes: they enhance the stability of the timber structure, in addition to housing the lift and stairwell.

Although Ascent is considered the tallest timber skyscraper in the world, its construction wouldn’t have been possible without a reinforced concrete core. However, it was precisely the lightness of timber that enabled rapid construction, maximising both the living and working space. The timber external walls are in fact 40% slimmer than those made from other building materials, yet still offer the same level of thermal insulation performance. Moreover, solid timber improves indoor comfort thanks to its thermal insulation and soundproofing properties, along with the advantage of rapid assembly.

Steel-timber hybrid structure: lightness and strength

Another highly effective combination is that of steel and timber. In this configuration, steel is used for the vertical frame, while timber is employed for the horizontal elements. A major benefit of this hybrid approach is dry construction: eliminating the use of concrete shortens construction times and prevents moisture release, thus reducing the risk of humidity build-up and damage to the timber finishes.

The combined use of steel and timber results in lighter and more flexible hybrid buildings, reducing overall weight without compromising safety. This construction system optimises load distribution, improving structural stability and increasing the building’s sustainability.

The Sara Kulturhus in Skellefteå, Sweden, is a notable example of a hybrid building combining timber and steel. Standing 80 metres tall across 20 storeys, it is one of Europe's tallest timber buildings.

Hybrid buildings in concrete, steel and timber

Some hybrid buildings incorporate all three materials to optimise load distribution. In these configurations, concrete serves as the rigid structural core, while steel and timber are combined to deliver lightness, insulation and resistance to seismic stresses.

Hybrid structures: all the advantages

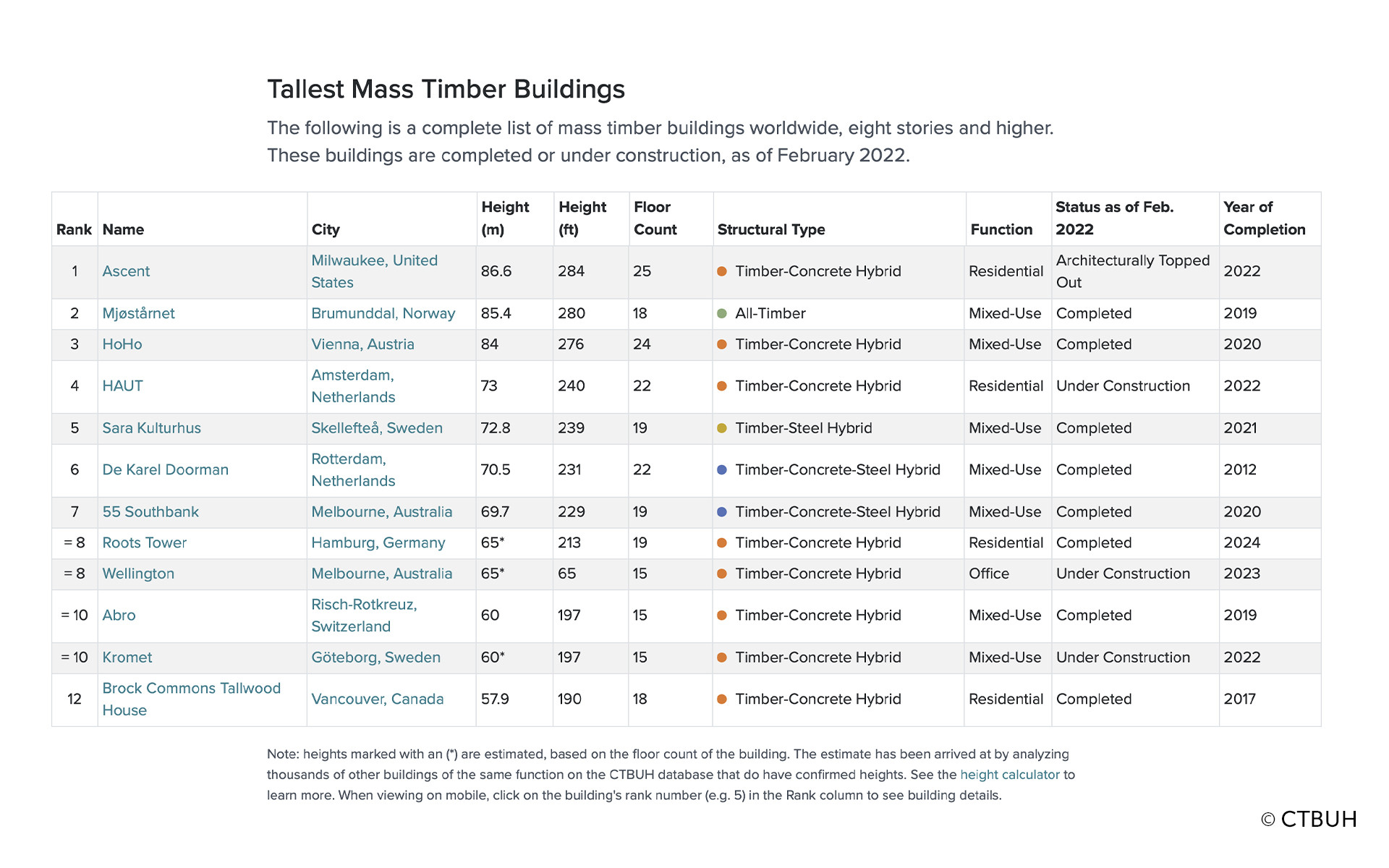

According to a CTBUH study*, as of the end of 2022, nine of the world’s ten tallest timber buildings were hybrid structures, further highlighting the growing role this technology plays in contemporary construction.

The technical advantages of hybrid construction are indisputable:

1. Greater structural strength

The combined use of materials with complementary properties allows for the construction of more resilient buildings:

Steel: excellent tensile and flexural strength.

Concrete: high stiffness and outstanding compressive strength; ideal for foundations and stiff cores.

Timber: high strength-to-weight ratio and energy-dissipating capacity of steel connectors, making it ideal for seismic zones.

Seismic performance

Timber-to-steel connections improve the absorption of seismic forces.

Timber-to-concrete hybrid structures increase lateral resistance.

Reduced overall weight

Using timber and steel reduces the load on foundations and simplifies the design of multi-storey buildings, improving the even distribution of weight. This enables a reduced reliance on heavy materials such as concrete, thus improving sustainability while lowering overall construction costs.

Faster construction times

Modular solutions using steel and prefabricated timber reduce assembly times compared to buildings in reinforced concrete. Prefabrication reduces on-site construction time and improves build precision, minimising errors and lowering maintenance costs.

5. Greater sustainability

Solid timber improves thermal insulation.

Steel-to-timber hybrid structures minimise thermal bridging.

Integrating smart technologies into hybrid buildings enhances energy efficiency, lowers energy consumption and improves indoor comfort.

*https://www.ctbuh.org/research/projects/the-future-potential-of-steel-timber-hybrid-buildings

Hybrid building costs: a long-term investment

One of the key obstacles to the more widespread adoption of hybrid structures is their upfront cost, which is typically 5–10% higher than that of conventional steel or concrete buildings. However, over the medium to long term, energy savings and reduced maintenance costs help offset the initial investment.

Research conducted by the CTBUH indicates that lower energy consumption and greater on-site efficiency can enable full cost recovery within 10 to 15 years. Additionally, the use of prefabricated components contributes to lower construction costs by leveraging economies of scale.

Another factor influencing costs is the increasing availability of advanced technological solutions for designing and managing hybrid buildings. Tools such as Building Information Modelling (BIM) software support more precise planning, less prone to errors, reducing waste and significantly improving construction efficiency.

Regulatory evolution

Until a few years ago, building codes were heavily geared towards traditional materials such as concrete and steel, while timber was mainly used in low-rise structures. Today, advances in construction techniques and material innovation have prompted regulatory revisions, enabling the use of timber in multi-storey buildings.

The introduction of the Eurocode 5 standard for timber structures marked a key milestone in this process, laying the groundwork for the design of more complex, multi-storey timber buildings. At the same time, increasing awareness of sustainability and the pressing need to cut carbon emissions have led governments to promote the uptake of eco-friendly solutions, such as hybrid construction. In 2027, with the adoption of Eurocode 8 – the second generation of European standards – new parameters will be established for timber and hybrid structures, paving the way for even more advanced design practices.

Rothoblaas’ contribution to hybrid construction

Rothoblaas offers advanced solutions for the construction of hybrid buildings in a range of configurations, including timber-to-steel, timber-to-concrete and timber-to-steel-to-concrete.

One example is the TC FUSION system, which supports prefabricated construction and the development of stiff CLT floor slabs, ensuring exceptional strength and stability.

Rothoblaas supports hybrid construction by producing specialised connectors and fasteners, designed to optimise the connection between different materials and meet the demands of complex projects. These include ALUMEGA, which stands out for its versatility in beam-to-beam and beam-to-column joints, as well as its ability to accommodate column rotation while maintaining shear strength under gravitational loads from floor slabs. ALUMEGA allows multiple modules to be combined, effectively resolving all connections across timber, concrete and steel.

The RADIAL and RING connectors are ideal for prefabrication and the assembly/disassembly of modules.

For high-strength fastenings, HUS turned washers are the perfect solution to enhance the axial resistance of HBS countersunk head screws.

With these and other solutions – including fastenings, thermal insulation and soundproofing – Rothoblaas provides designers and builders with the tools needed to construct efficient, durable and sustainable hybrid buildings, meeting the challenges of modern construction.

Hybrid construction is not only central to modern structural design – it represents a genuine opportunity for development. That’s why Rothoblaas promotes professional training through specialised courses and supports research through initiatives such as the BUILD THE (IM)POSSIBLE contest, dedicated to the design of hybrid buildings. In this context, the challenge is to develop innovative solutions for the design and construction of hybrid buildings, where timber engineering meets other materials. The contest website features the “PRODUCTS FOR HYBRID BUILDINGS” brochure, a useful resource for anyone committed to optimising construction processes: DOWNLOAD

All rights reserved

Technical Details

- 国家:

- Any

- 产品:

- TC FUSION ALUMEGA RADIAL RING HUS HBS