Design for Disassembly: a new approach to sustainability in timber construction

Design for Disassembly (DfD) is a design approach aimed at facilitating the disassembly and reuse of building components, promoting sustainability and circular economy practices within the construction industry. A beneficial method that helps extend the lifecycle of materials, reduces waste and facilitates building maintenance.

To explore the application of DfD in timber structures, we interviewed Andrea Polastri, structural engineer and researcher at the Institute of BioEconomy (IBE) of the Italian National Research Council (CNR), where he heads the Mechanical Testing Laboratory.

1. Could you briefly explain what the Institute of BioEconomy (IBE) does, and tell us about its specific role within the Italian National Research Council (CNR)?

The IBE is an institute of the Italian National Research Council dedicated to research across several fields, including agrometeorology, climate change and the study of timber. The San Michele all'Adige branch, particularly the Mechanical Testing Laboratory, specialises in the mechanical characterisation of structural timber, as well as certification testing on products such as CLT and its related components. A key aspect of our work involves collaborating with companies, allowing us to develop and test next-generation solutions in the field of timber construction.

2. Your latest research focuses on RING, a new connector for CLT structures. What were the initial goals, and why is the study of timber connections so important today, especially in terms of sustainability?

The aim of the research was to develop a connector that not only guaranteed high mechanical performance but was also easy to assemble and disassemble. While various solutions already exist on the market, most involve nailed or screwed plates, often resulting in more complex assembly and disassembly procedures.

We focused on prefabrication, developing a system that enabled practical preassembly off-site, and simplified installation on-site. The connector needed to reduce the risk of error, be installable by a single operator, and allow for the connection to be integrated into the wall, improving structural strength and reducing eccentric loading.

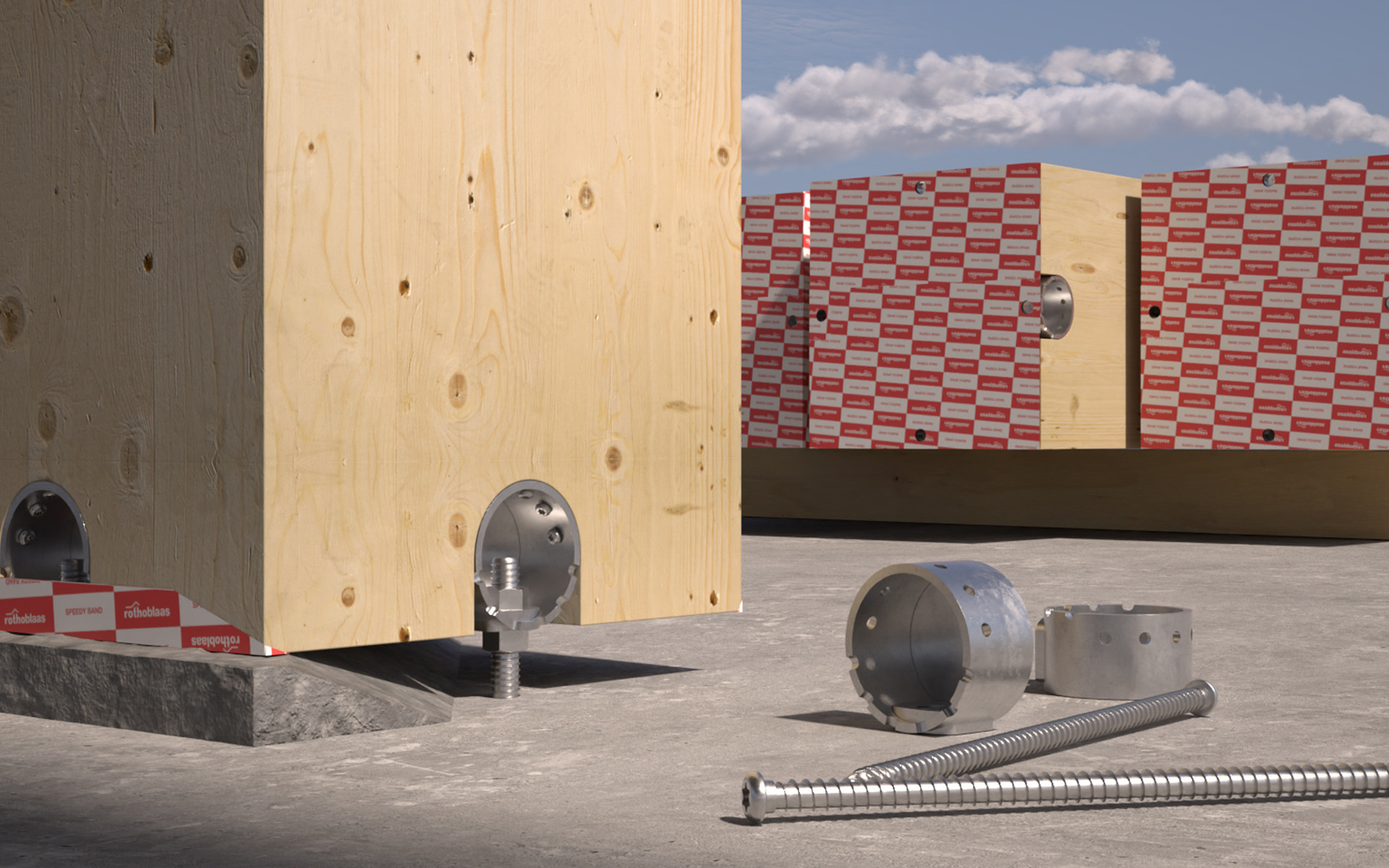

These requirements led to the development of RING60T and RING90C.

RING60T is a tube-shaped connector designed to join timber elements in various configurations (wall-to-wall, wall-to-floor, etc.). It was developed to provide both versatility and strength in structural applications.

RING90C is an optimised version dedicated to Design for Disassembly. It uses a single bolt for timber-to-timber, timber-to-concrete and timber-to-steel connections, allowing for quick and easy disassembly.

Design for Disassembly responds to the increasing demand for prefabricated and temporary buildings, such as those used for the Olympics and other major sporting events, making it essential to have connection systems that support fast and efficient assembly and disassembly. Design for Disassembly is the future.

3. What is Design for Assembly? Could you give us a clear definition of what Design for Disassembly truly means, and why it is such a crucial concept for the future of timber construction?

Design for Disassembly is a design approach that involves constructing buildings whose components can be easily disassembled, recovered and reused.

Its importance for the future of timber construction lies in its ability to promote sustainability, reduce demolition waste and support the long-term adaptability and maintenance of buildings.

4. So, “RING” was designed to satisfy the principles of Design for Disassembly. What features make it particularly suitable?

The RING connector, and in particular RING90C, is designed for easy installation and removal, minimising the risk of errors during assembly. The connector incorporates guides that simplify screw installation, allowing assembly by a single operator working on only one side of the wall. Moreover, being integrated within the wall, the connector provides improved mechanical strength and reduces eccentric loading. One bolt is all it takes, and it's secured.

5. Prefabrication and assembly: In your article, you highlight that the RING connector is designed to simplify operations, both off-site and on-site. How do these aspects tie in with Design for Disassembly?

Prefabrication allows the assembly of components in a controlled environment, ensuring greater precision and quality. Projects designed with DfD principles in mind must account for the use of connections suitable for disassembly right from the outset. Prefabrication allows the accurate installation of connectors off-site, ensuring higher quality and reducing both assembly time and the exposure of timber elements to weathering. The use of standardised components further streamlines both assembly and disassembly operations.

6. You conducted over 100 experimental tests for this research. Can you share some of the more interesting results?

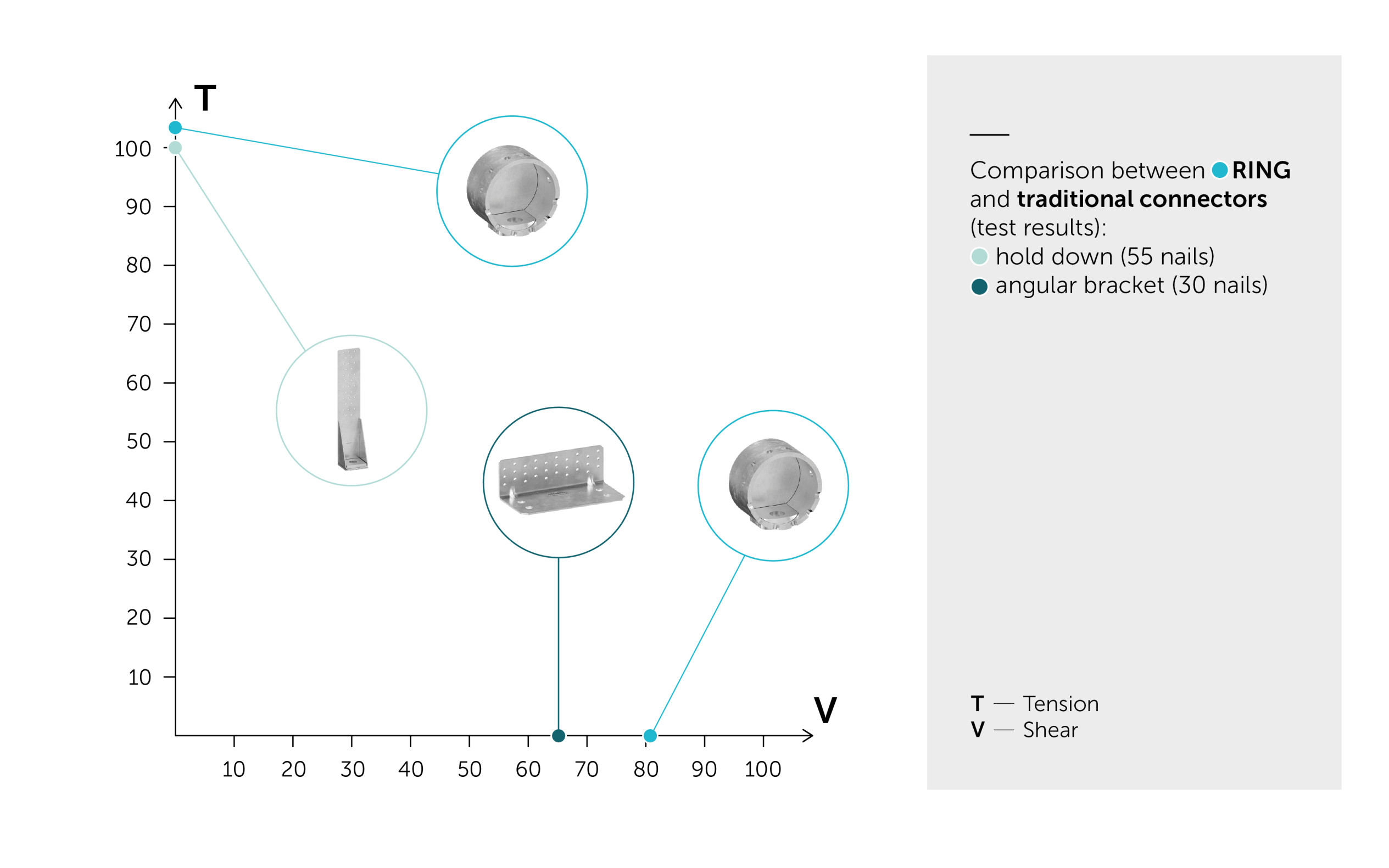

The findings showed that the RING connector provides strength comparable to that of traditional connectors, but with a more compact design. Additionally, the connector demonstrated ductile behaviour, with no brittle or sudden failures, thus ensuring greater structural safety.

Failure occurs at a high deformation level, having mobilised substantial ductility. Ductile failure means that the connection deforms gradually rather than failing suddenly, avoiding a domino effect and improving the mechanical performance of the joint.

7. The RING connector is also suitable for hybrid structures in timber and other materials. Can you explain how?

The RING connector has been tested in various configurations, including timber-to-timber, timber-to-steel and timber-to-concrete connections, and subjected to different types of stress, including shear, tensile and angled forces.

Even when the connection is used to join timber and other materials, its structural performance remains unchanged.

This means that the certifications, supported by experimental tests and a clear, thorough calculation method, can also be extended to hybrid configurations, for example timber-to-steel structures. Born from a collaboration between research and industry, the project combines expertise and shared goals to improve existing solutions and develop new ones. A journey that, in close collaboration with Rothoblaas, has led to the development of a connector specifically dedicated to Design for Disassembly: not just any connector, but the connector.

8. You mentioned working closely with Rothoblaas. How crucial is industrial support in promoting the philosophy of Design for Disassembly on a wider scale?

The development of products such as RING, as well as many other solutions featured in the Rothoblaas catalogue, is key to promoting this approach to construction. In some cases, industry even anticipates market needs, providing tools that make Design for Disassembly a practical and viable choice. This ongoing investment in the philosophy of DfD is reflected in the ever-expanding range of connection systems dedicated to DfD, including SLOT, RADIAL and RING.

All rights reserved

Technical Details

- Companies:

- Istituto per la BioEconomia (IBE), Consiglio Nazionale delle Ricerche (CNR)

- 国家:

- Any

- 产品:

- RING SLOT RADIAL