Acoustics, fire and static

One profile to tame them all

The World Health Organization (WHO) defines health not only as the absence of disease, but as a state of complete physical, mental and social well-being. Structural timber, besides being environmentally friendly, positively affects well-being in living and working environments. Nevertheless, it does have acoustic performance challenges.

Specific techniques such as decoupling, aimed at interrupting the transmission of vibrations through structures, are used to tackle these issues. Layers of resilient products are used to isolate rigid elements, thus preventing the spread of vibration and associated noise. Nevertheless, this impacts both fire resistance and statics. In order to design correctly, it is important to know to what extent.

Sound

Architectural acoustics, which is a branch of acoustics, focuses on the comprehension and manipulation of sounds in architectural spaces. In this field, sound can be categorized into two main types based on the method of transmission: airborne noise (sound that travels through air) and structural noise (vibrations that propagate through building elements, including between non-contiguous spaces, including vibrations generated by footsteps).

In timber buildings, sound insulation is a particularly complex issue, and that is why Rothoblaas has invested heavily in research and development. The products in the SOUNDPROOFING SOLUTIONS catalogue have undergone hundreds of tests and studies in cooperation with prestigious institutions (ETH Zurich, Institute of Structural Engineering & Swiss Timber Solutions AG, Universities of Bologna, Graz and Innsbruck). This results in a selection of products that provide different acoustic performance depending on the context and have also been tested for fire and moisture resistance. Laboratory measurements, static tests, durability tests, moisture checks and fire behaviour studies provide designers with consistent data that corresponds to actual site conditions. The material is available within the catalogue, technical manuals and MyProject design software, which automatically calculates natural frequency, sound transmission and damping.

Of all the products available, XYLOFON represents the newest addition to the range of resilient profiles. Certified according to ETA, it is suitable for sound insulation of structures with medium to high loads and multi-storey buildings.

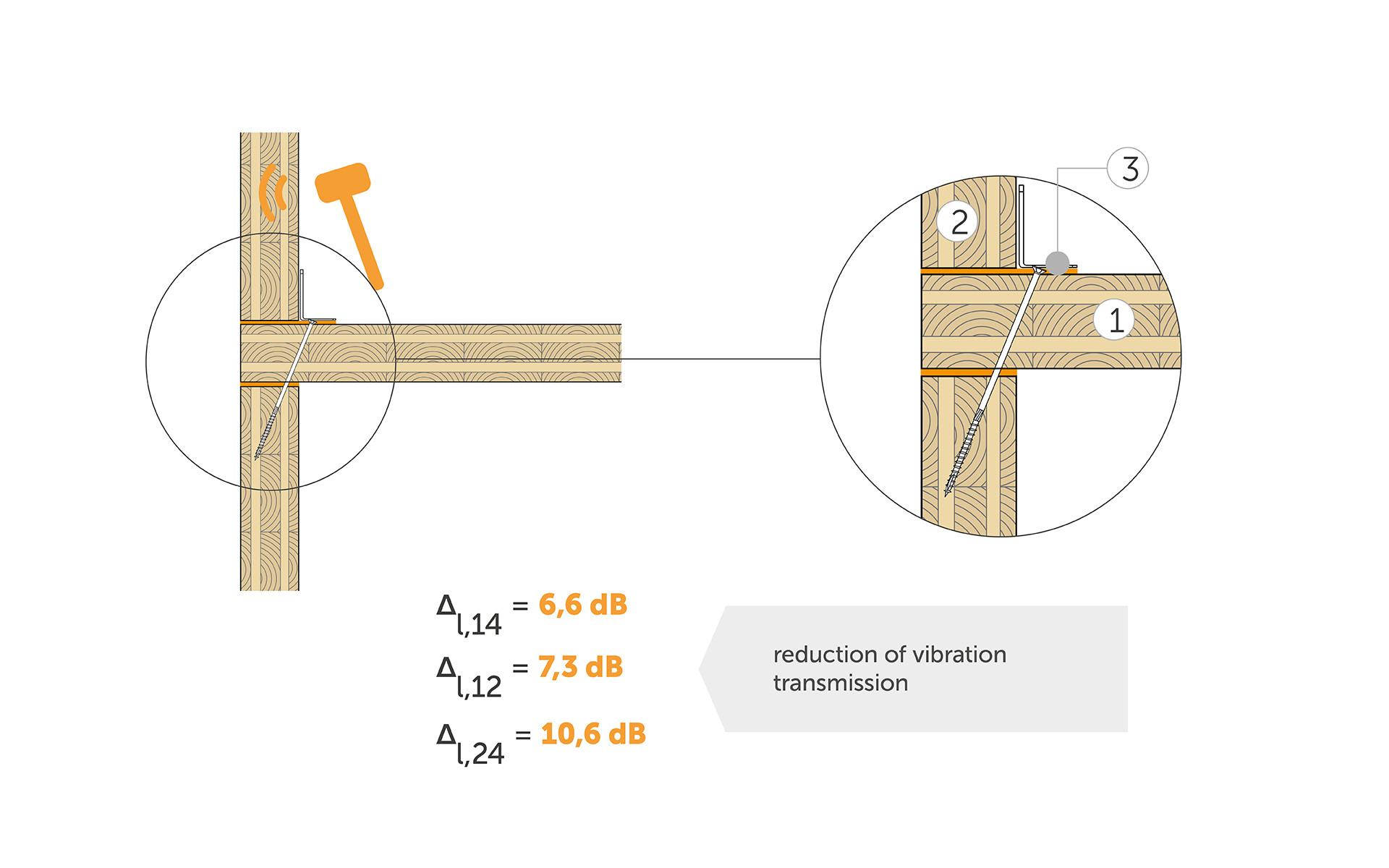

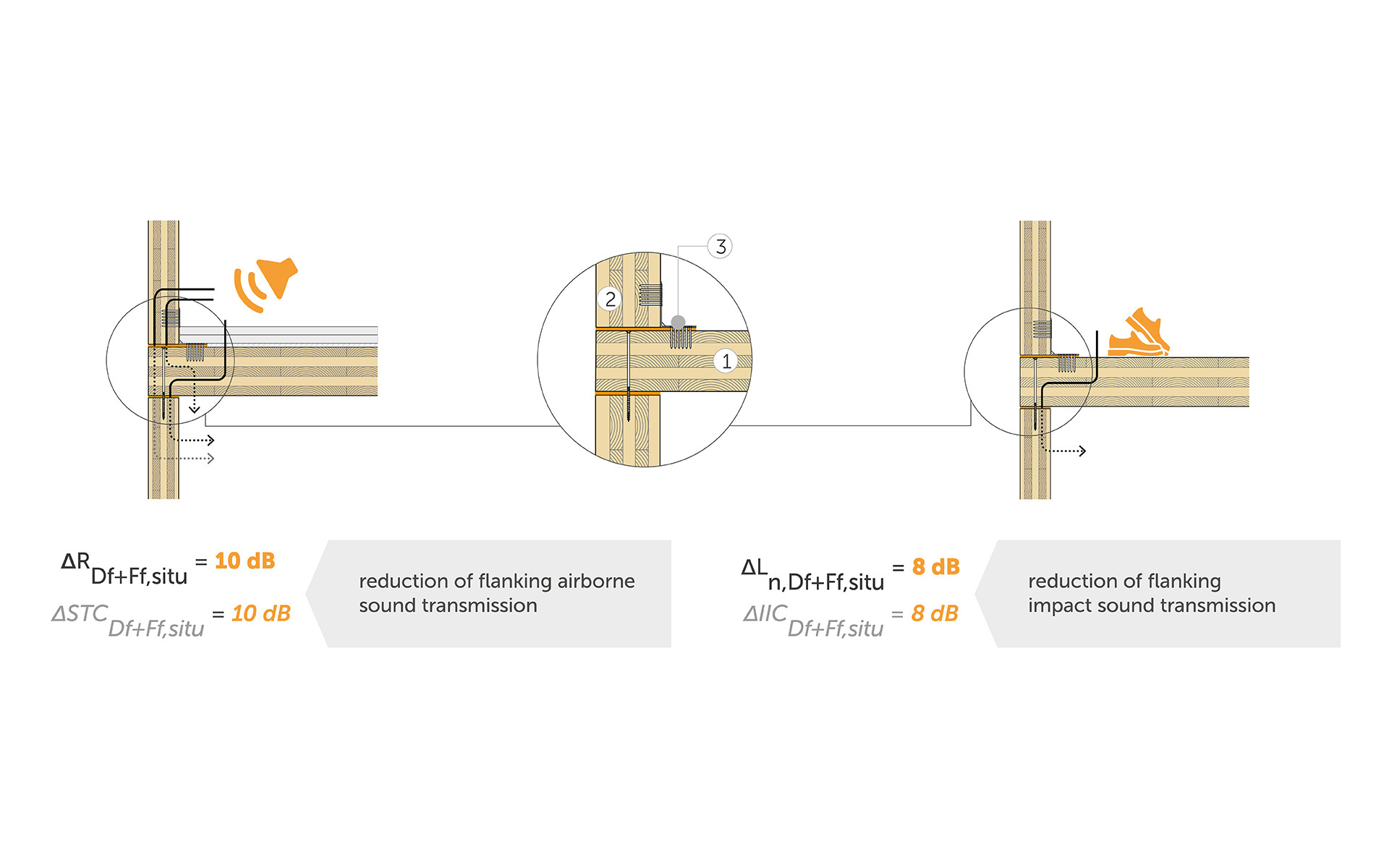

The profile decouples flanking transmission paths and reduces impact and structural sound transmission by up to 15 dB. It was tested as part of the FLANKSOUND PROJECT according to ISO 10848 by the University of Bologna and consequently certified.

Fire

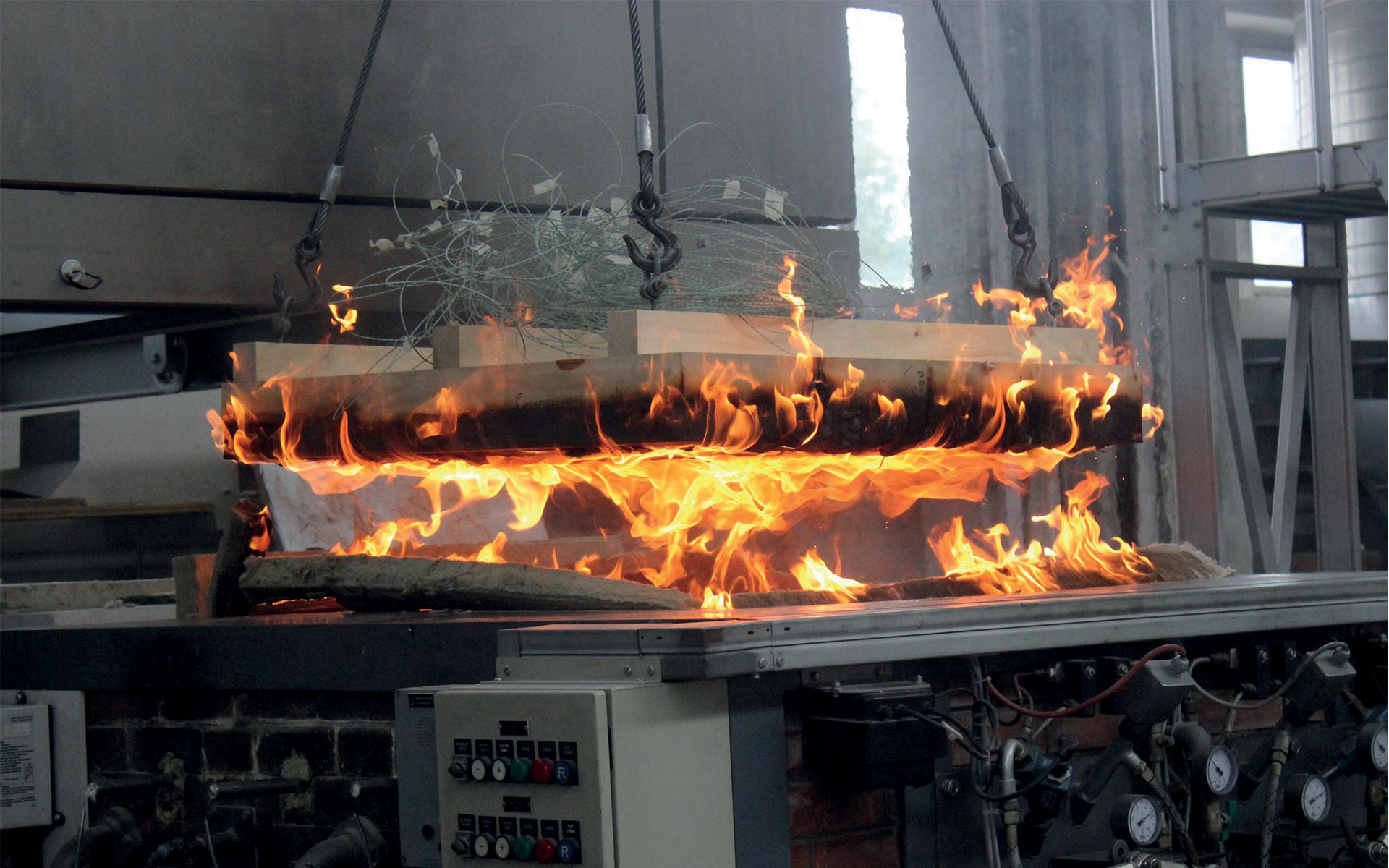

As a high-performance acoustic profile, XYLOFON can deal with the challenge of flanking noise, but what is its performance in fire protection? In order to improve fire design recommendations for XYLOFON profiles, we have tested the "shadow effect" phenomenon, which can be observed when the XYLOFON profile is slightly set back from the timber surface.

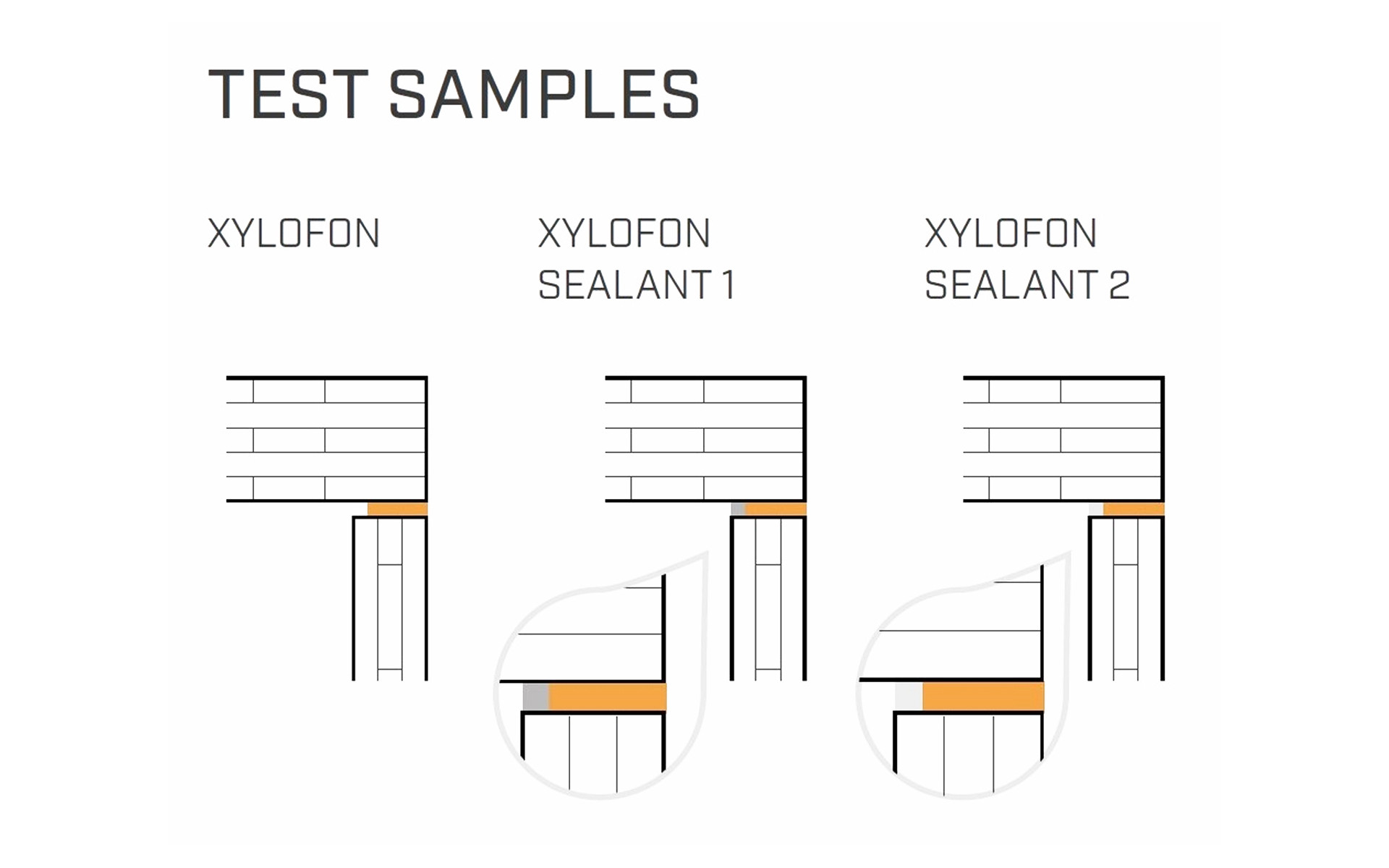

For the purpose of comparing the performance of XYLOFON joints with the performance of joints with fire-retardant sealant, we tested three different configurations, with the XYLOFON profile alone, with a first fireproof sealant, and then with a second fireproof sealant filling the gap.

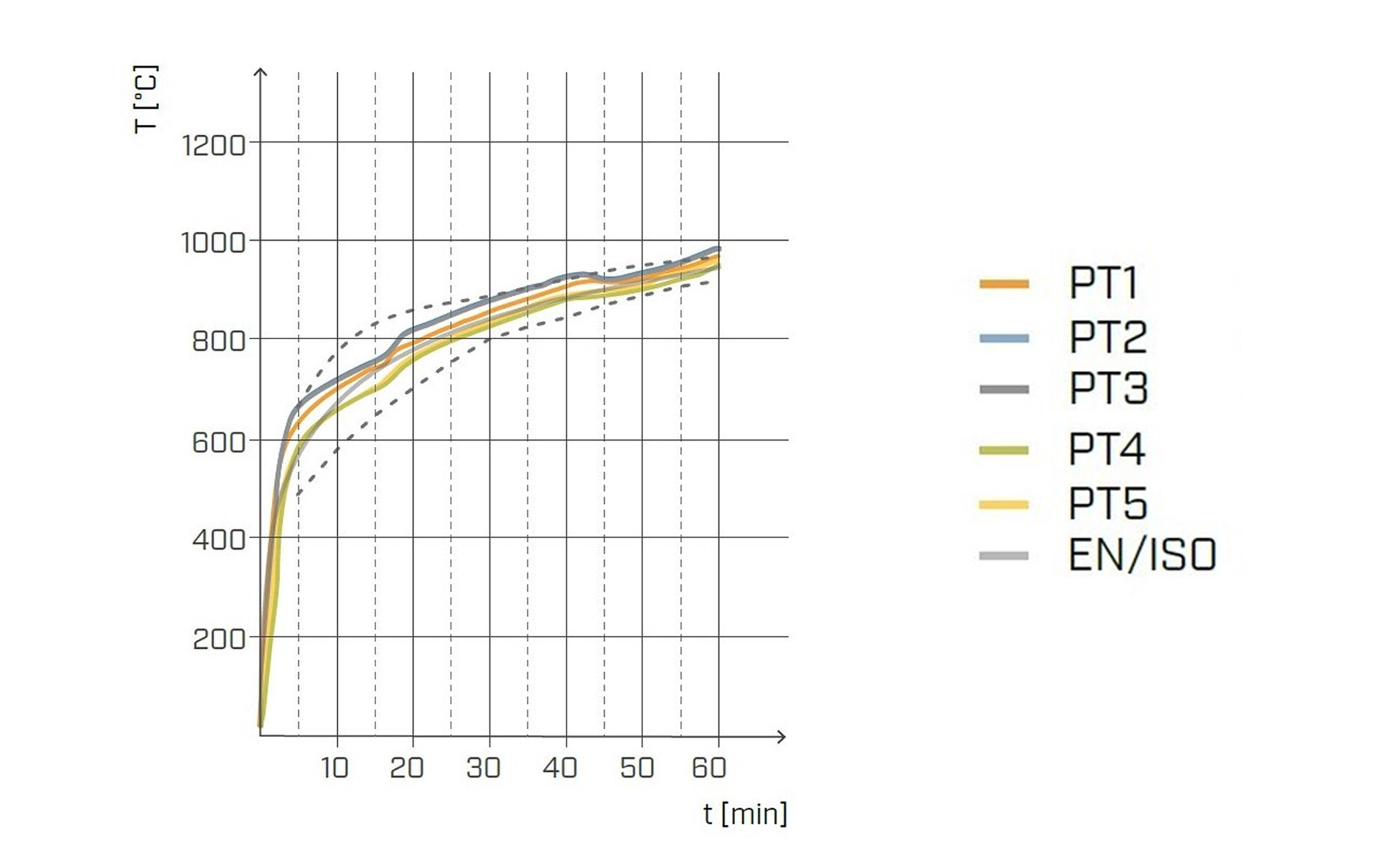

Five thermocouples (PT1-5) were placed to record temperature changes at various depths of the specimen during the fire test phase. The temperature changes were drawn on the following temperature/time graph.

The test was stopped after 60 minutes. For all configurations tested, the temperature of the surface not exposed to fire remained approximately at room temperature, showing no change in colour.

Results

As it was expected, the opening that contained only 100 mm of XYLOFON showed the greatest loss of thickness due to its carbonization. All three joints showed similar temperature development curves.

Therefore, the solution with 100 mm of XYLOFON can be affirmed to achieve EI 60 without the need for additional fire protection.

Static

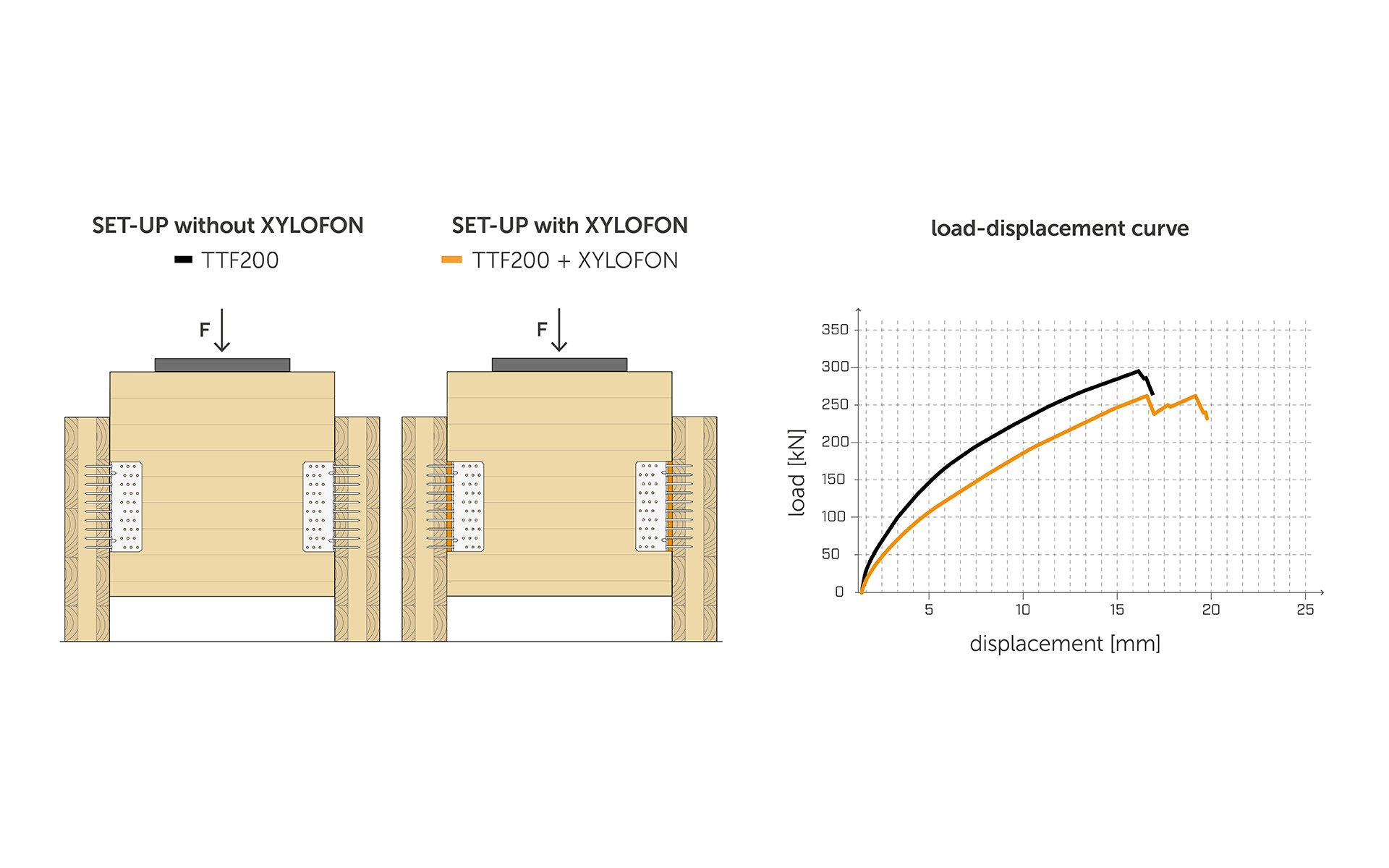

Resilient profiles for example XYLOFON can also be inserted inside structural connections to mitigate the acoustic bridge, but the influence of the resilient profile on the stiffness and strength of the connection should not be neglected.

It is important to have thin, low compressible resilient profiles and certified connectors with high strengths even with the resilient profile in between. The resilient profiles developed by Rothoblaas to reduce flanking sound transmission have been optimised to ensure excellent acoustic performance, as declared in the European Technical Assessment (ETA-23/0061 and ETA-23/0193).

The following experimental results provide the necessary data for proper acoustic design in the presence of structural connections.

The floor (1) is made of 160 mm 5-layer CLT and is decoupled with XYLOFON from the walls (2) made of 100 mm 5-layer CLT panels. The floor was fastened with HBS 6 x 240 mm screws at a distance of 300 mm and 10 TITAN + XYLOFON PLATE (3) TTN240 angle brackets with LBS 5 x 70 screws (72 screws each angle bracket).

The floor (1) is made of 100 mm 5-layer CLT and is decoupled with XYLOFON from the walls (2) made of 100 mm 5-layer CLT panels. The floor was fastened with 6 HBS partially threaded HBS Ø8 x 240 mm, pitch 440 mm and (2) NINO angle brackets (3) with XYLOFON PLATE resilient profile with 5 x 50 screws (31 screws per angle bracket).

Tests according to EN 26891 were carried out in the laboratories of the CNR/IBE in San Michele All'Adige and the University of Bologna. The test specimens, assembled with TITAN and NINO angle brackets with XYLOFON 35 resilient profile (6 mm thick), were brought to failure to investigate the load at 15 mm, the maximum load, and the relative displacements. The experimental campaigns allowed to obtain the force-displacement curves with and without an interposed resilient profile.

Certifications

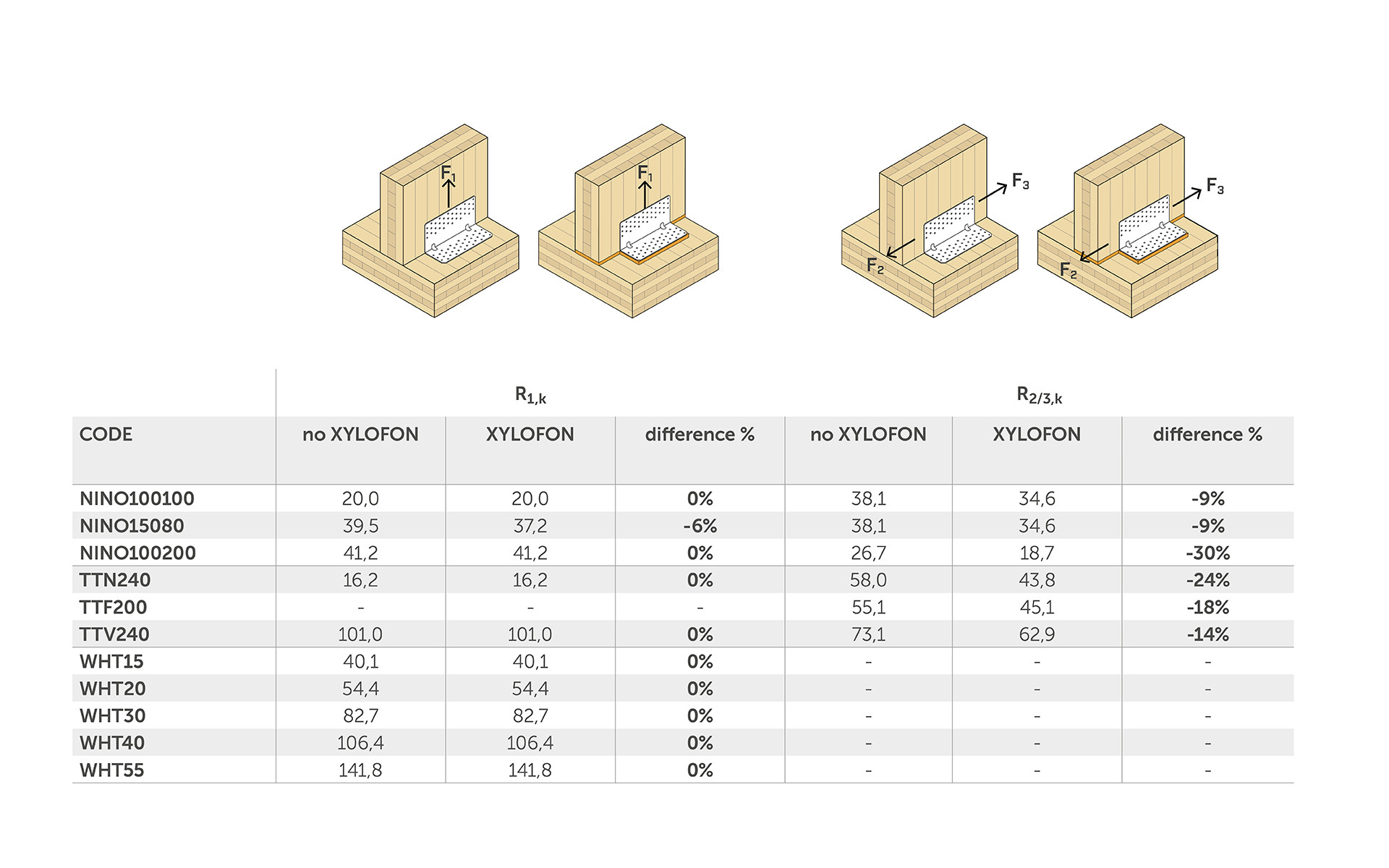

ETA-11/0496 (TITAN), ETA-22/0089 (NINO) and ETA-23/0813 (WHT) certifications declare the strength values of the angle brackets with or without interposed resilient profile. The certified strength values are exceptional even in the presence of a resilient profile, with the influence on strength limited to a few percentage points. This is made possible by the reduced thickness of the XYLOFON resilient profile (6 mm) and the inherent characteristics of the special polyurethane compound.

Tests show that the resilient profile results in both a decrease in stiffness and strength. This effect must be properly considered by the structural designer.

ETA-certified resistances for the most significant fastening configurations are shown in the table.

In summary

A holistic approach to design allows for integrated solutions to challenges related to acoustics, fire and statics in timber construction. Collectively tested and certified products such as XYLOFON, NINO, TITAN, WHT, HBS, and LBS ensure reliable performance and offer a comprehensive approach to ensuring safety and comfort in living and working environments.

All rights reserved

Technical Details

- 国家:

- Any

- 产品:

- XYLOFON XYLOFON PLATE TITAN SILENT LBS NINO HBS WHT